TRICHLOROETHYLENE (TCE)

Fact sheet

Trichloroethylene (TCE) is a common solvent, widely used in vapor degreasing, as a chemical intermediate, as part of cleaning solvent mixtures and as a solvent in adhesives. Due to the availability of economically viable, safer alternatives as well as stricter regulations, TCE use has declined steadily. TURI continues to provide technical and financial support to help businesses find safer safer alternatives (learn more).

People who drink water containing TCE over many years could experience liver problems and may have an increased risk of developing liver or kidney cancer. TCE also has genotoxic and immunotoxic potential, and some studies indicate that it may be a teratogen. There is also increasing evidence supporting the association between TCE exposure and non-Hodgkin lymphoma, several reproductive and developmental toxicity end points, including infertility in males and females, impaired fetal growth, and cardiac teratogenesis.

Due to its serious adverse effects on human health and the environment, TCE is subject to multiple regulations at the state, federal and international levels. TCE was designated as a higher hazard substance under the Massachusetts Toxics Use Reduction Act (TURA) in January 2008, which reduces the associated reporting threshold to 1,000 lb/year (approximately 70 gallons). In December 2024, EPA issued a final rule regulating TCE. The rule bans the manufacture (including import), processing, and distribution in commerce of TCE for all uses, with longer compliance timeframes and stringent worker protections for some processing and industrial and commercial uses until the prohibitions come into effect. The rule will protect consumers, workers, occupational non-users and bystanders from the harmful health effects of TCE.

TCE Facts

-

Health and Environment

TCE Fact Sheet: Toxicity data is constantly evolving and as such the data presented in this health and environment section are valid as of July 30, 2021. Updated TURA data is available at www.turadata.org.

Exposure Routes

Particularly large exposures, primarily via inhalation, may occur when workers clean metal parts in a vapor degreaser.

TCE is reported by the EPA to be the most prevalent solvent contaminating groundwater at superfund sites in the United States. The general public may be exposed to TCE by drinking, breathing or bathing in contaminated water. The third National Health and Nutrition Examination Survey suggested that approximately 10% of the population had detectable levels of TCE in their blood.

Human Health Effects

Acute Exposure

Acute (short-term) exposure to TCE vapors can cause central nervous system (CNS) effects (e.g., light-headedness, drowsiness, headache and giddiness) and may lead to unconsciousness or be fatal. At very high exposure levels, TCE can sensitize the heart to the effects of adrenaline and similar agents, which may lead to sudden cardiac arrest. In addition, TCE may irritate the respiratory tract at high vapor concentrations, and may be lethal at concentrations exceeding 1000 ppm. Repeated or prolonged contact with the chemical in liquid or mist form can cause irritation of the skin and eyes. Direct exposure to liquid TCE defats the skin, causing redness, blistering and scaling.

Chronic Exposure

Frequent, prolonged exposures to organic solvents in general can have long-lasting and possibly permanent effects on the nervous system. Chronic exposure to TCE in excess of recommended occupational limits has been associated with damage to the liver and kidneys.

People who drink water containing TCE over many years could experience liver problems and may have an increased risk of developing liver and kidney cancer. TCE also has genotoxic and immunotoxic potential, and some studies indicate that it may be a teratogen. There is also increasing evidence supporting the association between TCE exposure and non-Hodgkin lymphoma.

Cancer Risk

Several agencies have investigated TCE’s association with cancer. The US National Toxicology Program classifies TCE as “known to be a human carcinogen.” The International Agency for Research on Cancer (IARC) lists TCE as Group 1, carcinogenic to humans and EPA has characterized it is “carcinogenic in humans by all routes of exposure.”

Reproductive/Developmental Effects

Evidence from animal and epidemiologic studies suggests that several reproductive and developmental toxicity end points may be associated with TCE exposure, including infertility in males and females, impaired fetal growth, and cardiac teratogenesis. The US Agency for Toxic Substance and Disease Registry Public Health Statement for TCE, concluded that there is a relationship between exposure to TCE and an increased risk of reproductive effects in males, however evidence is more limited for females.

Environmental Hazards

TCE most often enters the environment via fugitive emissions from metal degreasing industries and by spills or accidental releases to air, soil and water. Because of its high vapor pressure and low rate of adsorption in soil TCE evaporates fairly rapidly when released to soil. However, where it persists it can percolate rapidly through sandy soil thereby reaching groundwater. Chemical and biological degradation of TCE in water are expected to be very slow. TCE is not expected to accumulate in aquatic organisms or to adsorb onto sediment; however it is toxic to aquatic organisms.

When released to the atmosphere, TCE remains in the vapor phase. Once in the air about half of the TCE will break down within a week. When TCE is broken down in the air, phosgene, a significant lung irritant, can be formed. In the body, TCE may break down into dichloroacetic acid, trichloroacetic acid, chloral hydrate, and 2-chloroacetaldehyde. These byproducts have been shown to be toxic to animals and may be toxic to humans.

Endnotes:

U.S Department of Health and Human Services, Household Products Database. Chemical Information, Trichloroethylene, 2008, and Third National Health and Nutrition Examination Survey (NHANES III, 1988-1994): Multiply Imputed Data Set, 2001; National Toxicology Program, 14th Report on Carcinogens: Trichloroethylene; ATSDR, Public Health Statement for Trichloroethylene; Toxicology Data Network Hazardous Substances Data Bank, Trichloroethylene; ATSDR, Medical Management Guidelines for Trichloroethylene; California Department of Health Services Hazard Evaluation System and Information Service, Fact Sheet: Trichloroethylene; US EPA, Ground Water & Drinking Water Consumer Factsheet on: Trichloroethylene; National Academy Press, Assessing the Human Health Risks of Trichloroethylene: Key Scientific Issues, 2006; US EPA Technology Transfer Network Air Toxics Website. Trichloroethylene; Toxics Use Reduction Institute, Policy Analysis, Higher Hazard Substance Designation Recommendation: Trichloroethylene; Ichihara, et al. Neurological Disorders in Three Workers Exposed to 1-Bromopropane, 2002.

-

Use

TCE Fact Sheet: This use section was updated in December 2021.

TCE was first produced in the early twentieth century and was used as a general anesthetic until the late 1970’s. TCE was also used as a solvent for extraction of palm, coconut and soybean oils, spices, hops and the decaffeination of coffee. The United States Food and Drug Administration banned these uses as well as use in cosmetics and drug production in the 1970s.

In 2015, approximately 172 million pounds of TCE was manufactured or imported in the US. Over 80% of TCE’s annual production volume is used as an intermediate in the manufacture of hydrofluorocarbon. Approximately 15% of TCE production volume is used as a degreasing solvent, leaving approximately 2% for other uses, including consumer uses. (EPA 2018)

Metal Cleaning and Degreasing

TCE is used as a degreasing solvent in the metal finishing, automotive and aerospace industries. TCE is used as a solvent for degreasing soft metals such as aluminum and for cleaning steel before galvanizing. TCE has many properties that make it an effective degreasing agent, including: high solvency; low flammability; non corrosiveness; and high stability. TCE is also relatively inexpensive and cleans thoroughly and quickly.

Chemical Intermediates

TCE in high purity grade is used as a feedstock to produce hydrofluorocarbon refrigerants and other chlorinated end products such as flame retardant chemicals. TCE is also used as a molecular-weight control agent in the manufacturer of polyvinyl chloride (PVC).

Miscellaneous uses

TCE is used as a solvent in adhesives and aerosol formulations. It is also used as a heat transfer medium as a solvent in electronics, printing, pulp and paper and in textile operations. Chlorinated solvents, such as TCE, are used in a number of operations in the textile industry. TCE is also used as a swelling agent in disperse dyeing of polyesters, for removal of basting threads, and in small quantities for scouring wool.

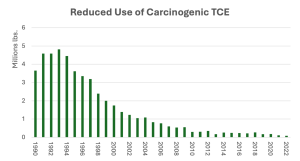

Since 1990 Massachusetts companies have reduced their use of TCE by more than 95%.

Massachusetts Uses

In 2019 almost 90% of TCE uses in Massachusetts (excluding chemical distribution) were associated with the cleaning of metal products.

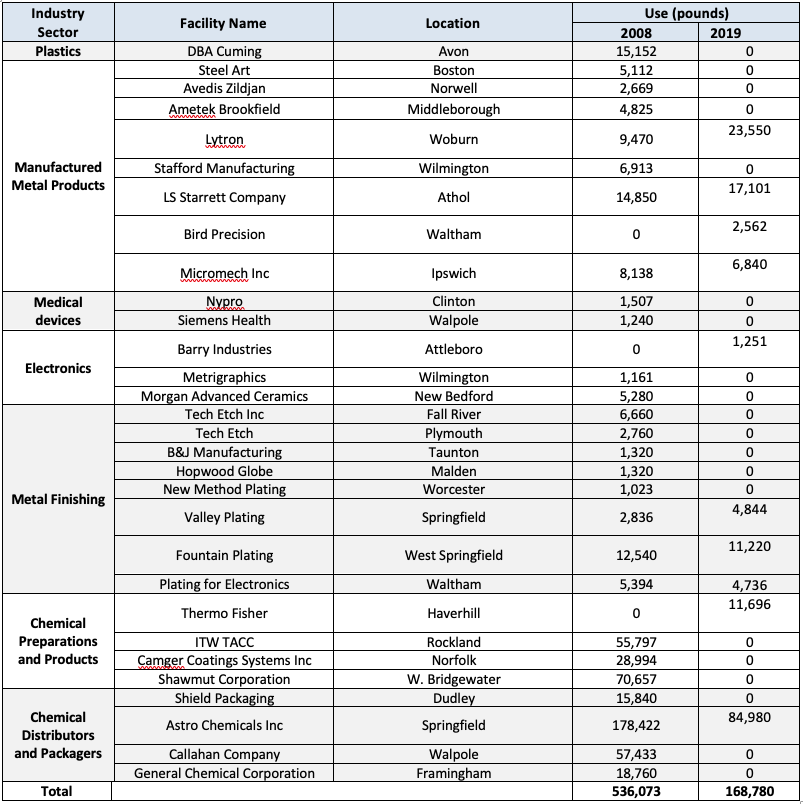

In 1990, the first filing year, 41 filers reported 3.6 million pounds of TCE. Overall, companies in Massachusetts have reduced their use of TCE by more than 95% since 1990. Most companies were able to reduce their use of TCE to below the 10,000 pound reporting threshold within 5 years of the beginning of the program. Between 1990 and 2007, the last year of TCE filing under regular thresholds, the number of filers dropped from 41 to 9. With the new lower reporting threshold (1,000 pounds/year starting in reporting year 2008) more companies began reporting on their use of TCE, with 27 filers in 2008. In 2019, the number of filers is down to 10. Table 1 shows the amount of TCE use reported in Massachusetts in the first year of Higher Hazard Substance reporting (2008) and in 2019.

Manufactured Metal Products

The manufactured metal products sector includes companies manufacturing products such as signs, musical instruments, measurement devices, jewelry, tools and other niche product lines. The companies in this sector used TCE to degrease or clean parts as part of their overall manufacturing processes. Many companies in this sector were able to reduce their use of TCE below reporting thresholds, typically within seven years. There are currently four filers in this sector.

Electronics and Wiring Devices

The electronics and wiring devices sector includes companies who manufacture passive resistance components, thin filmed components, and other miscellaneous electronic components. There is currently one company reporting in this sector.

Metal Finishing

Generally companies in this sector use TCE as a cleaner and degreaser for metal parts. All the original filers in the Metal Finishing sector reduced their use of TCE below reporting thresholds. Several of the companies in this sector are job shop operations whose customers largely dictate the processes required for plating. Three companies currently report in this sector.

Chemical Preparations and Products (including Rubber Products)

Massachusetts companies in this sector use TCE as a synthesis feedstock for such products as paints, adhesives and cleaners, as well as components in research chemistry. As of 2019, all the companies which used TCE as a synthesis feedstock for paints, adhesive, and cleaners have reduced use below reporting thresholds, while the company reporting use of TCE as a component in research chemicals reported for the first time in 2012.

Chemical Distributors and Packagers

One chemical distributor, representing over 50% of the total reported use of TCE in Massachusetts, reported processing TCE in 2019. The chemical distribution sector was not required to report in 1990, but it is likely that companies in this sector were using TCE at that time. These companies repackage TCE for bulk sales to their customers.

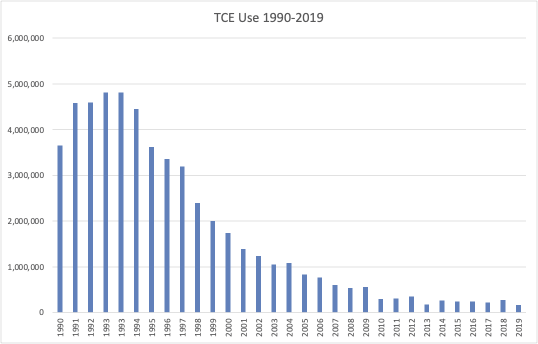

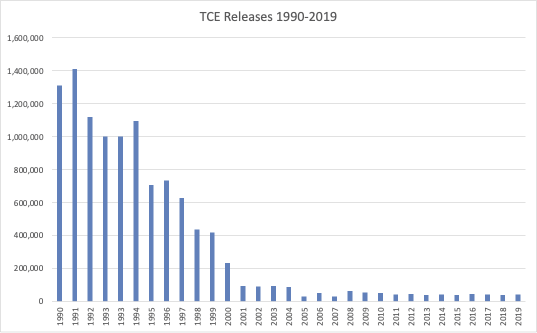

Summary of Inputs and Outputs

The two charts below illustrate the change from 1990 to 2019 in use and releases of TCE in Massachusetts. Use includes TCE that is manufactured or processed, as well as TCE that is “otherwise used” (i.e., ancillary uses that do not become incorporated into the final product). Releases include TCE that is released to the environment in air, water, or land.

Both use and releases of TCE were significantly reduced overall in the Commonwealth from 1990 to 2019. From 1990 to 2019 the total use of TCE, including otherwise used, manufactured or processed TCE, was reduced by 95% while the total releases of TCE, over the same time period was reduced by 97%.Endnotes:

Problem Formulation of the Risk Evaluation for Trichloroethylene. EPA May 2018.IARC. Monographs on the Evaluation of the Carcinogenic Risk of Chemicals to Man, 1972; Halogenated Solvents Industry Association, Trichloroethylene White Paper, 2001; Metropolitan Water District of Southern California Environmental Defense Fund, Source Reduction of Chlorinated Solvents-Textiles Manufacture. 1991; Toxics Use Reduction Institute TURA Data website, http://turadata.turi.org/

-

Alternatives

Alternatives for Adhesive and Paint Applications

Solvent-based adhesives are used in a variety of applications, from upholstered furniture and bedding applications to flexible vinyl mounting applications to substrate lamination applications. Adhesives use a carrier to transport, often in aerosol form, the tackifying resins and polymer solids that bond substrates together.

There are hundreds of adhesive formulations available on the market, many of which use a solvent carrier such as TCE. Typical solvent-based formulations use methylene chloride, acetone, acetone/heptane blends and n-propyl bromide. Each of these solvent-based adhesive formulations has potential human health and/or environmental health impacts that make them questionable alternatives to TCE-based formulations with respect to being “safer”. Other solvent adhesive formulations available use mineral spirits, petroleum solvents, petroleum distillates and VM&P naphthas.

However non-solvent based alternatives are available for many applications, including:

- Aqueous-based carriers using latex or latex-synthetic blends, and

- Hot melt applications, where a solvent-free 100% solids method is used in adhesion.

TCE is a relatively common carrier used in solvent-based paints. Alternatives include lower solvent content paints containing other solvents, or switching to aqueous-based latex paints. In addition, depending on the application, 100% solids paint processes such as powder coating may be appropriate alternatives.

The TURI lab has created an extensive database of safer alternatives to TCE (and other toxic solvents and cleaners) used for degreasing purposes. This database is available on the TURI lab website at www.cleanersolutions.org.

Alternatives for Degreasing

Over the years, preferred degreasing solvents have included chlorofluorocarbons (CFCs), trichloroethane (TCA), TCE and perchloroethylene (perc). CFCs and TCA were classified as Class I ozone-depleting substances and were phased out under the Clean Air Act in 1990.

For vapor degreasing, key physical properties include: low vapor pressure, low latent heat, low boiling point, low flash point, low surface tension and high solvency powers. TCE is generally used in degreasing operations because of its high boiling point, which allows the solvent to remove soils and waxes that lower-boiling solvents may not. The stability of TCE makes it particularly useful in airless degreasing systems. TCE is also used in “cold” degreasing applications, where the liquid is applied to the contaminant directly.

There are proven alternatives for metal degreasing, including hydrocarbon solvents (e.g., terpenes, alcohols, acetone, ketones, and acetates) and aqueous and semi-aqueous processes, including ultrasonic processing. Performance evaluations conducted by the TURI lab indicate that aqueous degreasing alternatives perform comparably to or better than TCE for a wide variety of contaminants and parts configurations. Resistance to adopting aqueous cleaning continues, however, and is often attributed to the following challenges:

- Reduced efficiency at producing clean and dry parts.

- Inability of the aqueous cleaner to get into small, blind holes. Solvents in the vapor form are more successful at cleaning these hard to reach areas.

- Reluctance to write off sunken capital associated with existing vapor degreasing equipment.

A number of “drop-in” solvent alternatives are available. However, some of these alternatives pose serious health or environmental concerns, so they are not considered safer alternatives. For example, 1-bromopropane (n-propyl bromide, or nPB) is a TCE alternative that is listed as a Higher Hazard Substance under TURA. Another example is 1,2 trans-dichloroethylene, which is also listed under TURA and also poses serious concerns.

An important consideration in degreasing applications is the need for removal of contaminants. Companies can evaluate their manufacturing operation to identify potential process modifications that would eliminate the need for this cleaning step.

Endnotes: International Programme on Chemical Safety and the Commission of the European Communities; WHO; Environ Health Criteria 50: Trichloroethylene, 1985; Morris, et al, 2000. Alternative Adhesive Technologies in the Foam Furniture and Bedding Industries: A Cleaner Technologies Substitutes Assessment. Volume 1: Cost and Performance Evaluation.

-

Regulatory Context

Due to its serious adverse effects on human and environmental health, TCE is subject to many regulations at the state and federal levels.

Federal Environmental Regulations

TSCA: In December 2024, EPA issued a final rule regulating TCE. The rule bans the manufacture (including import), processing, and distribution in commerce of TCE for all uses, with longer compliance timeframes and stringent worker protections for some processing and industrial and commercial uses until the prohibitions come into effect. The rule will protect consumers, workers, occupational non-users and bystanders from the harmful health effects of TCE.

EPCRA: Reportable under Toxic Release Inventory, Subject to Tier II reporting requirements; Reportable Quantity = 100 lbs.

CAA: Hazardous air pollutant; Vapor degreasers must meet the national emissions standards for halogenated solvents.

RCRA: Land disposal of TCE and all chlorinated solvents banned. Waste must be destroyed in incinerators or cement kilns. Characteristic Toxic Hazardous Waste: TCLP Threshold = 0.5 mg/L. Listed Hazardous Waste: U228, F001, F002, F024, F025, K018, K019, K020.

CWA – Water Quality Criteria: Based on fish/shellfish and water consumption = 2.5 μg/L; based on fish/shellfish consumption only = 30 μg/L.

SDWA: The maximum contaminant limit set for drinking water is 0.005 mg/L.

FDA: Maximum permissible level in bottled water = 0.005 mg/L; TCE may be used as a solvent in the manufacture of specified foods.

Federal Occupational Exposure Limits

OSHA: Permissible exposure limit (PEL) = 100 ppm; Ceiling Concentration = 200 ppm; Acceptable Peak Exposure = 300 ppm (5 minutes in any 2 hours).

ACGIH: Recommended threshold limit value – Time-Weighted Average Limit (TLV-TWA) = 10 ppm; Threshold Limit Value – Short Term Exposure Limit (TLV-STEL) = 25 ppm.

NIOSH: Recommended Exposure Limit (REL) = 25 ppm (as a 10-hour TWA); Immediately Dangerous to Life and Health (IDLH) = 1000 ppm; Listed as a potential occupational carcinogen.

State Regulations

Massachusetts: TCE is a designated high hazard substance, with an annual reporting threshold of 1,000 lbs; Threshold Effects Exposure Limit 24-hour average: 36.52 μg/m3 (6.80 ppb); Allowable Ambient Limit annual average: 0.61 μg/m3 (0.11 ppb)

California: PEL: 25 ppm (135 mg/m3); Listed as a carcinogen under Proposition 65.

Endnotes: Massachusetts Department of Environmental Protection Revised Air Guidelines; Mass DEP Standards and Guidelines for Contaminants in Massachusetts Drinking Waters, 2007; MassDEP Maximum Concentration of Contaminants for Toxicity Characteristic; California Department of Health Services Hazard Evaluation System and Information Service Fact Sheet: Trichloroethylene; NIOSH Pocket Guide http://www.cdc.gov/niosh/npg/pgintrod.html; US EPA, Ground Water & Drinking Water Consumer Factsheet on: Trichloroethylene; American Conference of Governmental Industrial Hygienists Threshold Limit Values for Chemical Substances and Physical Agents and Biological Exposure Indices, 2005.

-

Endnotes

TCE Fact Sheet

1. U.S Department of Health and Human Services, Household Products Database. Chemical Information, Trichloroethylene, 2008, and Third National Health and Nutrition Examination Survey (NHANES III, 1988-1994): Multiply Imputed Data Set, 2001; National Toxicology Program, 11th Report on Carcinogens: Trichloroethylene; ATSDR, Public Health Statement for Trichloroethylene; Toxicology Data Network Hazardous Substances Data Bank, Trichloroethylene; ATSDR, Medical Management Guidelines for Trichloroethylene; California Department of Health Services Hazard Evaluation System and Information Service, Fact Sheet: Trichloroethylene; US EPA, Ground Water & Drinking Water Consumer Factsheet on: Trichloroethylene; National Academy Press, Assessing the Human Health Risks of Trichloroethylene: Key Scientific Issues, 2006; US EPA Technology Transfer Network Air Toxics Website. Trichloroethylene; Toxics Use Reduction Institute, Policy Analysis, Higher Hazard Substance Designation Recommendation: Trichloroethylene; Ichihara, et al. Neurological Disorders in Three Workers Exposed to 1-Bromopropane, 2002.

2. Chemical Economics Handbook, 2002, 632.3000Y, SRI International; IARC. Monographs on the Evaluation of the Carcinogenic Risk of Chemicals to Man, 1972; Halogenated Solvents Industry Association, Trichloroethylene White Paper, 2001; Metropolitan Water District of Southern California Environmental Defense Fund, Source Reduction of Chlorinated Solvents-Textiles Manufacture. 1991; Toxics Use Reduction Institute TURA Data website, http://turadata.turi.org/

3. International Programme on Chemical Safety and the Commission of the European Communities; WHO; Environ Health Criteria 50: Trichloroethylene, 1985; Morris, et al, 2000. Alternative Adhesive Technologies in the Foam Furniture and Bedding Industries: A Cleaner Technologies Substitutes Assessment. Volume 1: Cost and Performance Evaluation.

4. Massachusetts Department of Environmental Protection Revised Air Guidelines; Mass DEP Standards and Guidelines for Contaminants in Massachusetts Drinking Waters, 2007; MassDEP Maximum Concentration of Contaminants for Toxicity Characteristic; California Department of Health Services Hazard Evaluation System and Information Service Fact Sheet: Trichloroethylene; NIOSH Pocket Guide http://www.cdc.gov/niosh/npg/pgintrod.html; US EPA, Ground Water & Drinking Water Consumer Factsheet on: Trichloroethylene; American Conference of Governmental Industrial Hygienists Threshold Limit Values for Chemical Substances and Physical Agents and Biological Exposure Indices, 2005.