Use Nationally and in Massachusetts

TCE Fact Sheet: This use section was updated in December 2021.

TCE was first produced in the early twentieth century and was used as a general anesthetic until the late 1970’s. TCE was also used as a solvent for extraction of palm, coconut and soybean oils, spices, hops and the decaffeination of coffee. The United States Food and Drug Administration banned these uses as well as use in cosmetics and drug production in the 1970s.

In 2015, approximately 172 million pounds of TCE was manufactured or imported in the US. Over 80% of TCE’s annual production volume is used as an intermediate in the manufacture of hydrofluorocarbon. Approximately 15% of TCE production volume is used as a degreasing solvent, leaving approximately 2% for other uses, including consumer uses. (EPA 2018)

Metal Cleaning and Degreasing

TCE is used as a degreasing solvent in the metal finishing, automotive and aerospace industries. TCE is used as a solvent for degreasing soft metals such as aluminum and for cleaning steel before galvanizing. TCE has many properties that make it an effective degreasing agent, including: high solvency; low flammability; non corrosiveness; and high stability. TCE is also relatively inexpensive and cleans thoroughly and quickly.

Chemical Intermediates

TCE in high purity grade is used as a feedstock to produce hydrofluorocarbon refrigerants and other chlorinated end products such as flame retardant chemicals. TCE is also used as a molecular-weight control agent in the manufacturer of polyvinyl chloride (PVC).

Miscellaneous uses

TCE is used as a solvent in adhesives and aerosol formulations. It is also used as a heat transfer medium as a solvent in electronics, printing, pulp and paper and in textile operations. Chlorinated solvents, such as TCE, are used in a number of operations in the textile industry. TCE is also used as a swelling agent in disperse dyeing of polyesters, for removal of basting threads, and in small quantities for scouring wool.

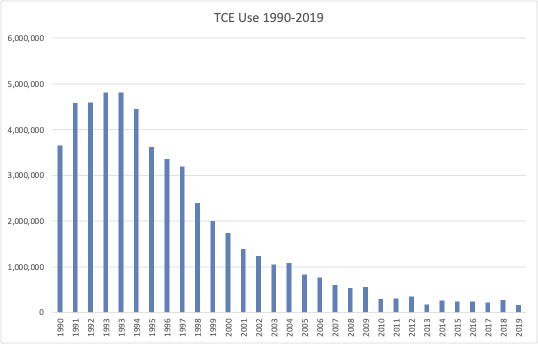

Since 1990 Massachusetts companies have reduced their use of TCE by more than 95%.

Massachusetts Uses

In 2019 almost 90% of TCE uses in Massachusetts (excluding chemical distribution) were associated with the cleaning of metal products.

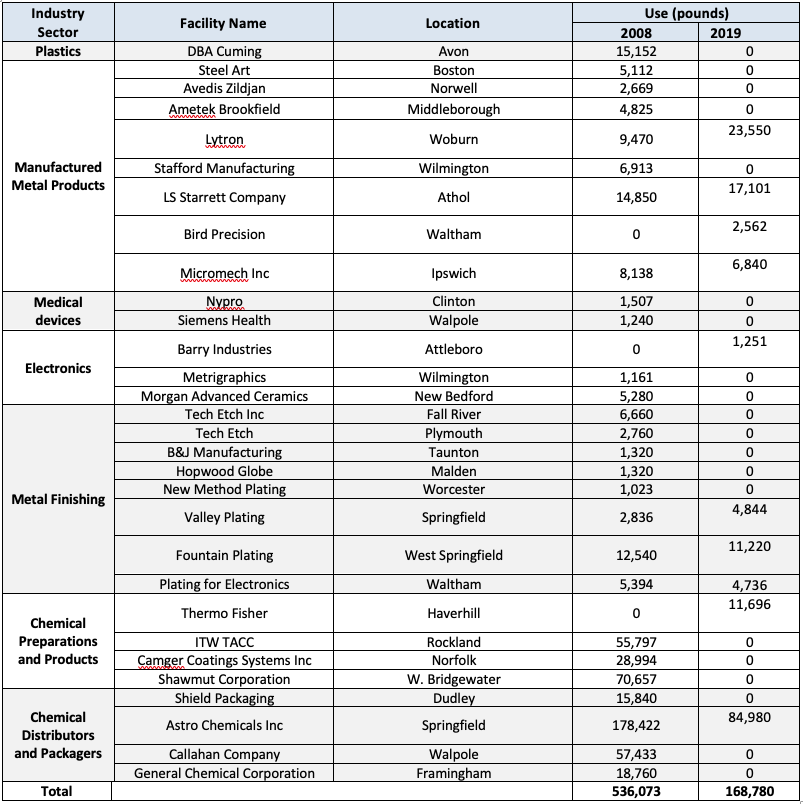

In 1990, the first filing year, 41 filers reported 3.6 million pounds of TCE. Overall, companies in Massachusetts have reduced their use of TCE by more than 95% since 1990. Most companies were able to reduce their use of TCE to below the 10,000 pound reporting threshold within 5 years of the beginning of the program. Between 1990 and 2007, the last year of TCE filing under regular thresholds, the number of filers dropped from 41 to 9. With the new lower reporting threshold (1,000 pounds/year starting in reporting year 2008) more companies began reporting on their use of TCE, with 27 filers in 2008. In 2019, the number of filers is down to 10. Table 1 shows the amount of TCE use reported in Massachusetts in the first year of Higher Hazard Substance reporting (2008) and in 2019.

Manufactured Metal Products

The manufactured metal products sector includes companies manufacturing products such as signs, musical instruments, measurement devices, jewelry, tools and other niche product lines. The companies in this sector used TCE to degrease or clean parts as part of their overall manufacturing processes. Many companies in this sector were able to reduce their use of TCE below reporting thresholds, typically within seven years. There are currently four filers in this sector.

Electronics and Wiring Devices

The electronics and wiring devices sector includes companies who manufacture passive resistance components, thin filmed components, and other miscellaneous electronic components. There is currently one company reporting in this sector.

Metal Finishing

Generally companies in this sector use TCE as a cleaner and degreaser for metal parts. All the original filers in the Metal Finishing sector reduced their use of TCE below reporting thresholds. Several of the companies in this sector are job shop operations whose customers largely dictate the processes required for plating. Three companies currently report in this sector.

Chemical Preparations and Products (including Rubber Products)

Massachusetts companies in this sector use TCE as a synthesis feedstock for such products as paints, adhesives and cleaners, as well as components in research chemistry. As of 2019, all the companies which used TCE as a synthesis feedstock for paints, adhesive, and cleaners have reduced use below reporting thresholds, while the company reporting use of TCE as a component in research chemicals reported for the first time in 2012.

Chemical Distributors and Packagers

One chemical distributor, representing over 50% of the total reported use of TCE in Massachusetts, reported processing TCE in 2019. The chemical distribution sector was not required to report in 1990, but it is likely that companies in this sector were using TCE at that time. These companies repackage TCE for bulk sales to their customers.

Summary of Inputs and Outputs

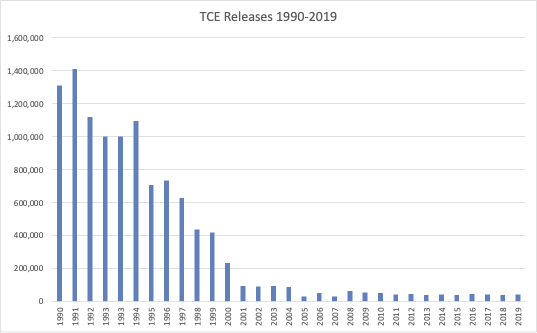

The two charts below illustrate the change from 1990 to 2019 in use and releases of TCE in Massachusetts. Use includes TCE that is manufactured or processed, as well as TCE that is “otherwise used” (i.e., ancillary uses that do not become incorporated into the final product). Releases include TCE that is released to the environment in air, water, or land.

Both use and releases of TCE were significantly reduced overall in the Commonwealth from 1990 to 2019. From 1990 to 2019 the total use of TCE, including otherwise used, manufactured or processed TCE, was reduced by 95% while the total releases of TCE, over the same time period was reduced by 97%.

Endnotes: Problem Formulation of the Risk Evaluation for Trichloroethylene. EPA May 2018.IARC. Monographs on the Evaluation of the Carcinogenic Risk of Chemicals to Man, 1972; Halogenated Solvents Industry Association, Trichloroethylene White Paper, 2001; Metropolitan Water District of Southern California Environmental Defense Fund, Source Reduction of Chlorinated Solvents-Textiles Manufacture. 1991; Toxics Use Reduction Institute TURA Data website, http://turadata.turi.org/