The Importance of Worker Engagement in Chemicals Management

Written By Agnes Cheng, Training Associate

Earlier this year, I had the unique opportunity to visit Flexcon, a family-owned business that has been a global leader in coating and lamination for nearly 70 years. Nestled in the small town of Spencer, Massachusetts, this company prides itself on its technical expertise and its commitment to delivering high-performance labeling and coating materials for sectors including healthcare, construction, and consumer products.

Upon arriving, I was greeted by Aaron Ellman, Senior Manager of Technology Development, who had invited us to lead a workshop on chemical hazard assessment and safer alternatives after learning about our training program. The visit began with a tour of the expansive manufacturing campus, and Mr. Ellman outlined the complex challenges faced by the company’s safety and technology teams. Flexcon operates in a fast-paced market, with demanding performance needs. I was impressed by the dedication and expertise of their safety team in conducting thorough health and safety evaluations for the wide range of formulations their company produces, and also recognized how challenging that job is.

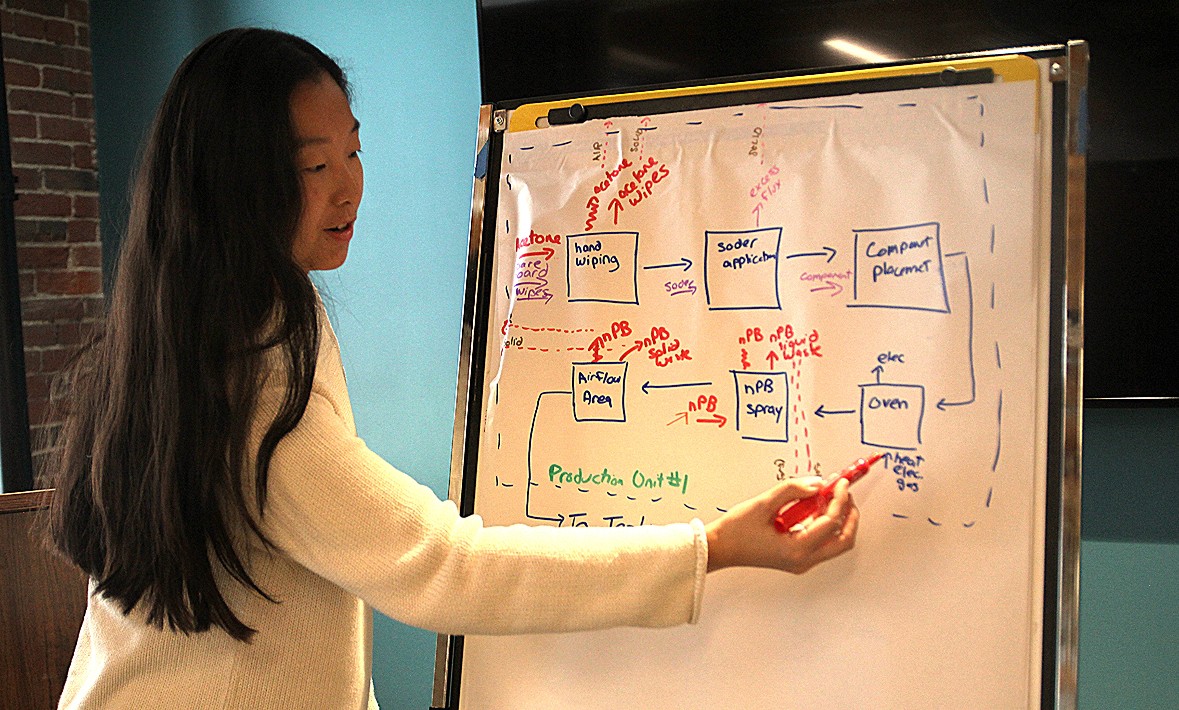

Unlike TURI’s typical site visits, which often focus on technical collaboration or laboratory-based support for evaluating alternative chemistries, this visit was focused on training. I was excited to lead a training designed to strengthen their team’s skills in chemical hazard assessment and finding safer alternatives; an inspiring step toward building lasting in-house expertise.

As Flexcon grows, Mr. Ellman shared that they’re focused on building awareness of chemical hazards across the company and equipping more employees with the knowledge and tools to make informed decisions. Their approach reflects a growing commitment not only to regulatory compliance, but to continuous improvement in worker health, environmental protection, and community safety.

Companies like Flexcon, which handle large volumes of chemicals, are regulated under Massachusetts’ Toxics Use Reduction Act (TURA), which requires them to report toxic chemical use and plan ways to reduce it. In these reporting and planning actions, meaningful worker involvement in chemicals management is more than a best practice; it is a legal requirement. Workers bring critical insight to the table, informed by their direct experience with operational processes and their exposure to hazardous substances. Their perspective is essential to effective toxics use reduction (TUR) planning and the successful implementation of safer practices.

Despite this, a significant barrier to open and productive dialogue is the knowledge gap that often exists between environmental health and safety (EH&S) professionals and other members of the workforce. EH&S staff typically possess specialized expertise in chemical hazards, regulatory requirements and risk assessment. However, their work may be siloed, confined to specific departments or only brought into broader view during required trainings or incident response. As a result, essential knowledge about chemical safety often does not extend beyond the EH&S team.

Expanding a safety-first culture requires more than policies; it requires empowering all employees with the knowledge to participate in conversations about chemical use and risk. Building a shared vocabulary around hazard characteristics, exposure pathways, and safer alternatives is a foundational step. When chemical knowledge is democratized rather than sequestered, facilities gain access to a wider range of perspectives that can drive innovation and identify practical, effective alternatives to hazardous chemicals.

Cultivating this shared knowledge ultimately strengthens a facility’s overall chemicals management strategy. It ensures that safety and sustainability are not limited to one department, but become shared values embedded across the organization.

After the workshop, we spoke with several members of Flexcon’s safety team. While the safety team brings decades of experience in environmental health and safety, many of the other participants were just beginning to engage with these complex topics, leaving the room with that wide-eyed expression that comes from trying to absorb a flood of new information. Learning about chemical hazards can indeed feel like drinking from a firehose, but Flexcon’s EH&S experts and leadership are committed to supporting ongoing learning through continued dialogue and training. Organizations like TURI, or our sister agency the Office of Technical Assistance and Technology, are here to assist with that education.

As I drove home that day, I was inspired by the effort Flexcon was making to initiate conversations about chemical hazard assessment and safer alternatives. While many challenges remain, this effort spearheaded by Mr. Ellman and his safety team not only supports compliance with laws like TURA, but also empowers workers to engage actively in safer, more sustainable decision-making.