Why Toxics Use Reduction Planning?

Written By Pam Eliason

1. What does it mean to be a TUR Planner and what does toxics use reduction mean for businesses and manufacturers?

Being a toxics use reduction planner boils down to being a champion for your company or client to find new ways to do what they do with less – or no?! – toxic chemicals. This is no small feat, especially for people who wear a gazillion hats at their workplace, or for folks who only touch base with their clients when asked. But with proper training, continuing education and the support of senior management, planners can guide their companies or clients toward more sustainable practices that promote agility and resiliency.

That’s what companies can experience when TUR planning is done in good faith – meaning it is more than a compliance activity, more than a one-and-done effort. When companies commit to the process, they find ways to save money, create a safer work environment, and shore up their products and processes against possible future chemical regulations or restrictions.

2. Why do companies need a TUR Planner?

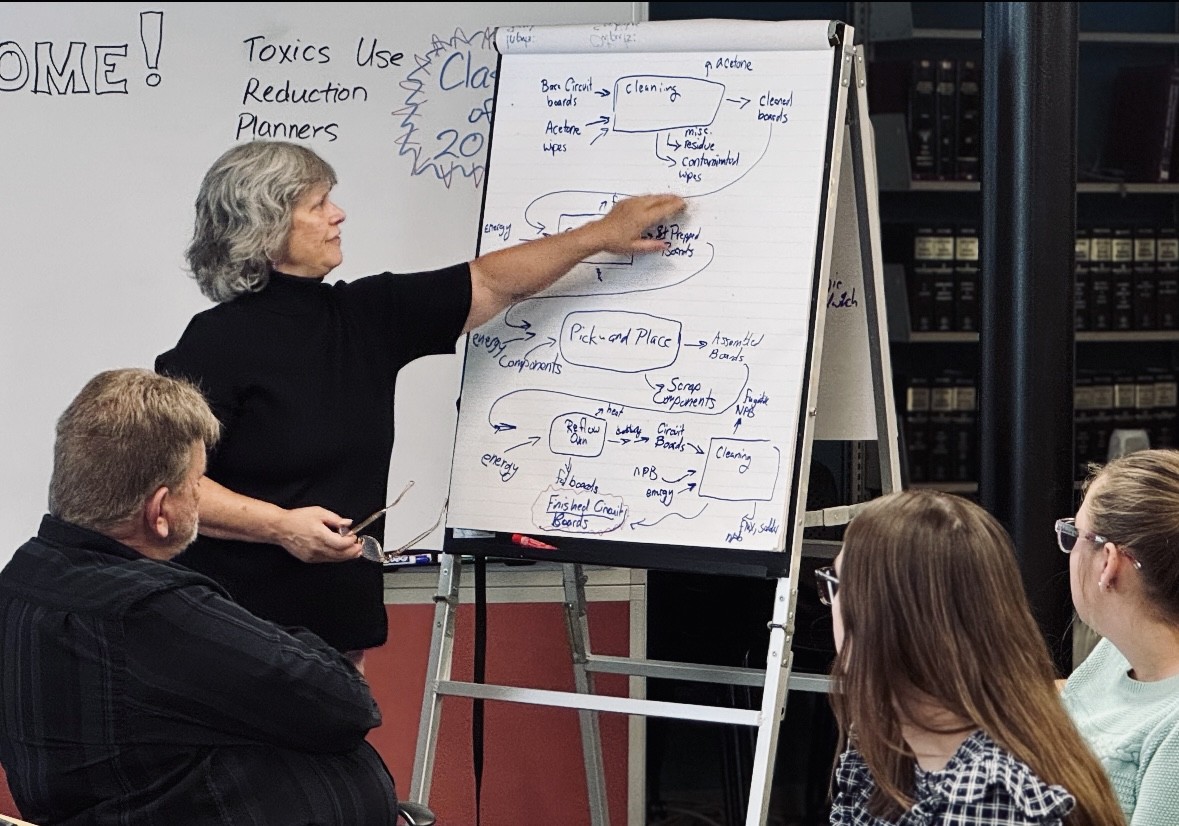

TUR planning is a systematic process that guides planners to understand why toxic chemicals are used (what their desired function is), where and how these chemicals enter and exit the various processes, and which changes could be implemented to support a safer, effective and affordable process, workplace and product.

It’s an investment for companies to hire a General Practice planner or to train their own staff to be their Limited Practice planner. But like any sound investment, it gives them access to new perspectives that can lead to highly profitable improvements in their practices. Companies that are part of international corporations suddenly find themselves leading their peers in implementing changes for sustainability. Smaller operations begin to engage with their workers, neighbors and public service providers in ways that improve morale, public relations and regulatory collaboration. These companies, large or small, become more agile when faced with new chemical-related challenges, and more resilient as regulatory or customer climates change.

3. How would someone interested in TUR Planning get started?

Well, they start by connecting with TURI’s training team! We’ll help them figure out next steps. Basically, there are two paths to becoming a certified TUR planner – through experience or through training and examination. Professionals who want to be the champion for TUR at their own company may be eligible to be certified by MassDEP as a Limited Practice planner if they have sufficient experience with their company in activities like process characterization, options identification and feasibility assessment. Consultants who wish to provide TUR planning services to their clients must take the examination route to certification as a General Practice planner. Once certified, all planners must maintain continuing education that expands their skills and supports their success. They can access all the training they need through TURI’s training events, including conferences, courses and webinars. https://www.turi.org/training-and-education/

4. What are the benefits of becoming a TUR Planner?

TUR planners learn and practice skills that are easily translated to other career paths. They learn how to dig deep, asking the tough questions, to find safer, affordable and effective alternatives to the status quo. Whether a company is required to look for options, or they see that long-term economic and market viability depends on making safer choices proactively, companies who work with TUR planners to assess chemical substitution or process redesign opportunities set themselves up for a competitive advantage in their field. Being the person who champions the planning process and the goal of reducing toxics is not only a challenging and satisfying activity in and of itself, it sets planners apart as contributors to the success of the company.

5. Can you share an example of how TUR Planning has impacted a company?

Transene Company Inc. manufactures process chemistries for the microelectronics industries. Their president, Christopher Christuk, has been a TUR planner for over a decade. Right there we can see that the company is committed to engaging in a good faith effort to reduce its use of toxics because their senior management takes the training and education offered by the TURA program so seriously.

When regulatory authorities around the world, including the TURA program, began looking at potential regulation of certain PFAS, Chris learned about the concerns associated with these chemicals at our bi-annual TUR conferences. He also learned about TURI’s academic research grant program, designed to research and develop safer alternatives to the use of toxics for specific applications. Chris reached out for support in developing alternative PFAS formulations that are not only safer, but also effective and affordable. Within 18 months the research team, in close collaboration with Transene, identified a safer formulation that Transene then switched the majority of their customers to. Not only was Transene able to provide a PFAS-free solution to their customers, they were also able to save money on chemical purchase and management costs while establishing themselves as leaders in their field.

6. Talk about your experience as the Director of Training at TURI and how that helps you equip planners with the tools they need to be successful?

When I started working at TURI I was involved in and eventually managed the industry and research programs. My background as a chemical and environmental engineer gave me great insight into the possibilities for manufacturers in a variety of industry sectors. I developed important relationships with many Massachusetts companies and their planners in this role.

I took over managing the training program upon the retirement of my predecessor, Mark Myles. Mark had set us on the path toward a more modern training format, creating a hybrid version of the flagship TUR planner certification course. As Training Director I’ve been able to build on the relationships I’ve made with our audience of MA companies and consultants and have also been able to further update and improve our course content and delivery. I’m always looking for ways to support the development of the next generation of professionals and to bring more of our planners to the front of the room to share their experiences and lessons learned.

Providing excellent training and education for our audience means partnering closely with planners to cover the topics they want and to maximize peer learning opportunities. Our planners need to be refreshed on the fundamentals of the TUR planning process, and they need to be kept abreast of evolving science and technology that supports their efforts to reduce use of toxics at their companies. The addition of peer learning assures them that what they are learning is also grounded in the reality faced by manufacturers, not just the theory of the practice.

What we do in the training program provides key elements needed for our planners to successfully champion toxics use reduction at their companies and with their clients.